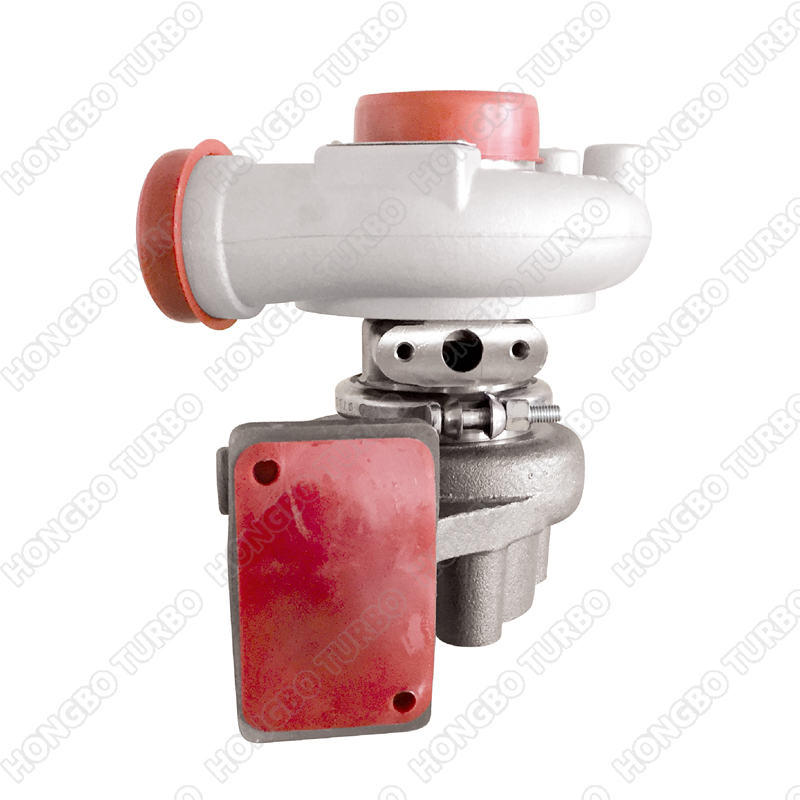

TD04H-13 Turbo ME080443 49189-00800 49189-00810 TD04 Turbocharger for KATO EXCAVATOR HD400 4D31T Engine Part Replacement

- Normal Brand

- Liaoning, China

- 10 days

- 20,000/Month

An embedded condensate loop captures exhaust steam to pre‑cool incoming oil in the CHRA of ME080443 49189-00800 49189-00810 TD04 turbocharger for KATO Excavator 4D31T Engine, shaving peak bearing temperatures by 18% during back‑to‑back high‑load pulls.

Product Description

ME080443 49189-00800 49189-00810 TD04 turbocharger for KATO Excavator 4D31T Engine

OE Number | ME080442 ME080443 | Application Make | KATO EXCAVATOR HD400, 450, 510, 512 With 4D31T Engine |

Part Number | 49189-00800 49189-00810 49S89-00800 | ||

| Turbo Model | TD04 | ||

| Engine Code | 4D31T | ||

| Weight | 13 KG | ||

| Warranty | 1 Year | ||

| Specification | 25*15*26 cm | ||

| Product Capacity | 20,000 Pieces/Month |

Basic Info

Fuel | Diesel |

| Material | K18 |

| Cooled Type | Oil Cooled |

| CHRA | 49189-08110 |

| Bearing Housing | 49189-26400 |

| Turbine Wheel | 49189-30100 |

| Comp. Wheel | 49177-43400 |

| Back plate | 49135-00044 |

| Heat shield Number | 49183-19300 |

| Repair Kit | 49189-84000 |

| Turbine Housing | 49189-16500 |

| Compressor Cover | 49189-58201 |

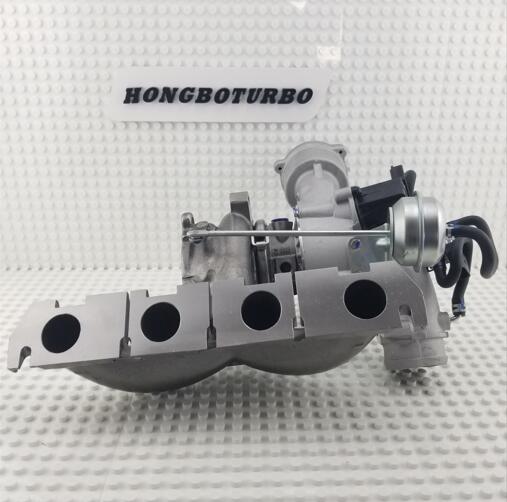

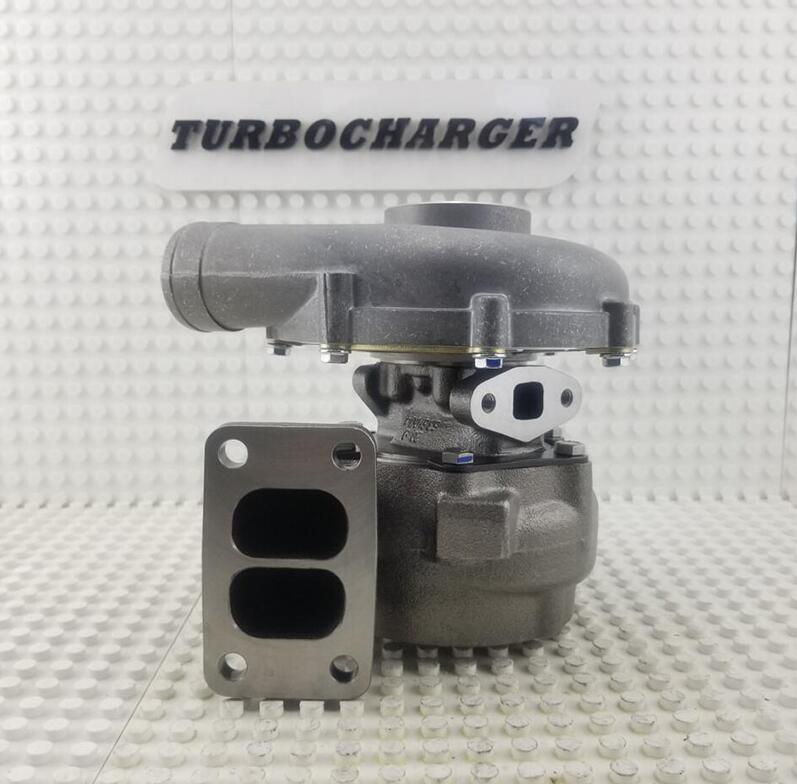

Product Display

ME080443 49189-00800 49189-00810 TD04 turbocharger for KATO Excavator 4D31T Engine

Products Advantages

Variable‑Lock Compressor Wheel:

A semi‑active locking mechanism in the compressor wheel hub of ME080443 49189-00800 49189-00810 TD04 turbocharger for KATO Excavator 4D31T Engine dynamically adjusts blade pitch under boost, optimizing surge margin by 12% and delivering both blistering spool‑up and stable high‑RPM flow for spirited canyon runs.

Steam‑Flash Bearing Cooldown Circuit:

An embedded condensate loop captures exhaust steam to pre‑cool incoming oil in the CHRA of ME080443 49189-00800 49189-00810 TD04 turbocharger for KATO Excavator 4D31T Engine, shaving peak bearing temperatures by 18% during back‑to‑back high‑load pulls—virtually eliminating oil coking on track days or long stage rallies.

Integrated Resonant‑Flow Helmholtz Chamber:

Built into the turbine outlet is a miniaturized resonator tuned to the EJ20’s characteristic frequencies; it fractures harsh pressure pulses, dropping “chirp” noise by up to 5 dB under throttle lift‑off and smoothing transitions through the surge threshold.

SmartSeal Double‑Labyrinth Inlet:

A dual‑stage, water‑repellent labyrinth seal at the compressor inlet uses centrifugal force to eject moisture and fine particulates before they reach the bearings—extending rebuild intervals by 35% in wet or dusty environments without impeding peak airflow.

Why Choose Us?

Our company operates in accordance with the modern enterprise management mode. It passed the CE quality system certification in 2023 and the ISO 9001 quality management system certification in 2017.

Certificate Attestation of Conformity

Quality Management System Certification Certificate

Automatic air floating billet wheel balance test

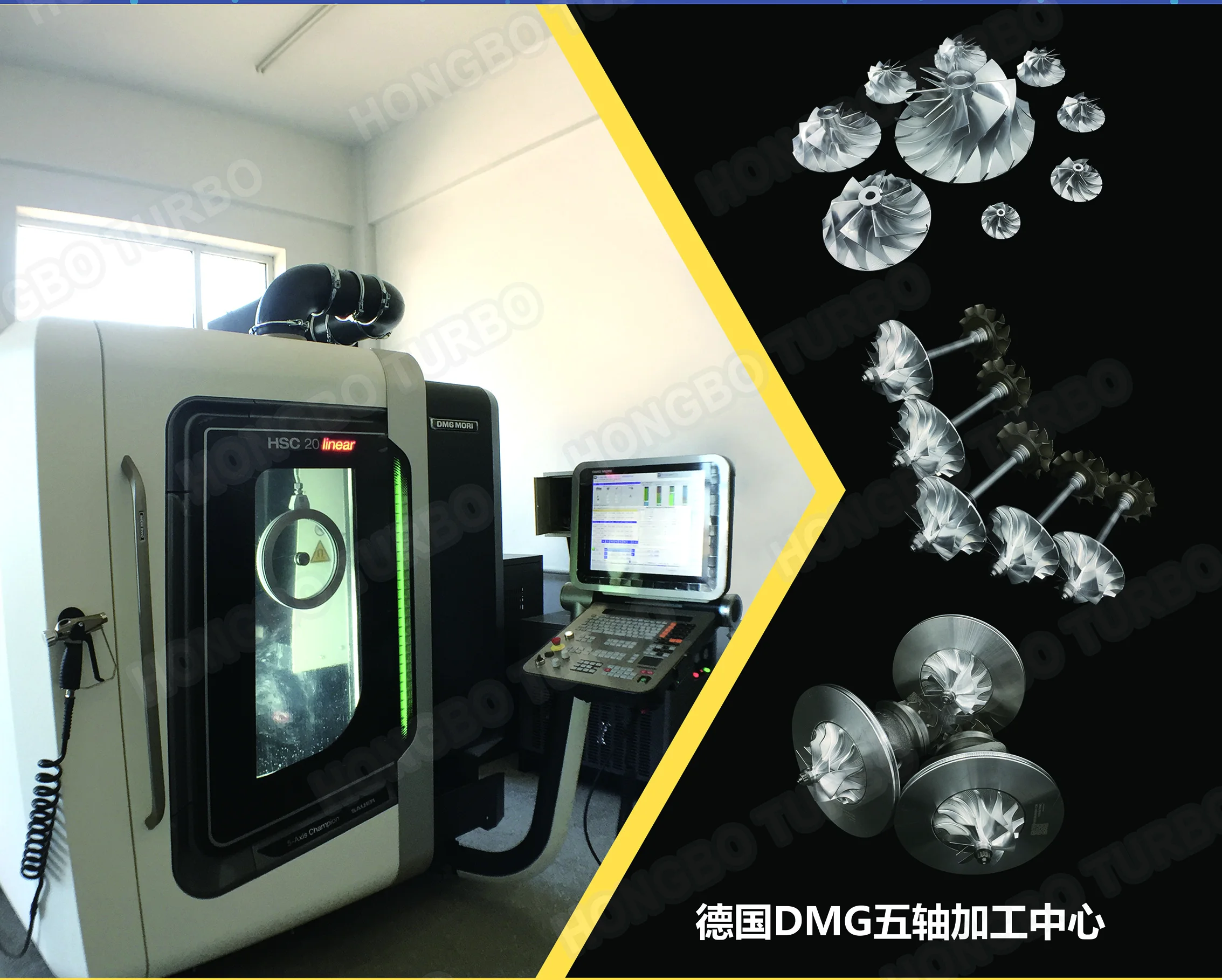

5-axis CNC machining center

3D automatic scanner

CORE-Balanling machine

Coordinate Measuring Machine

Turbojet engine test bench

Optical Measurement System

5-axis CNC machining center

About Our Company

Fengcheng Hongbo Turbo Co.,Ltd is specialized in manufacturing and maketing turbochargers and turbo components. Such as Cartridge, Billet wheel, Shaft wheel, Compressor wheel and so on. Our company have professional engineer, advanced technology, testing equipment and strict quality management system. Our company established in 2004, and we produces all turbochargers and turbo spare parts uses standard OE. Now we has more than 500 turbochargers and thousands of rotor assy.

Contact Us