SJ60F Turbocharger T74801002 with SJ60F-1E engine for perkins K18 material

- Normal Brand

- Liaoning,China

- 10 Days

- 20000 Pieces/Month

Perkins K18 models, the SJ60F Turbocharger T74801002 is paired with the SJ60F - 1E engine. Relying on advanced R & D technology and using high - quality materials such as K18, it has strong production capabilities. Widely applied in construction machinery and other scenarios, verified by cooperation cases, it features stable performance, helping equipment run efficiently, with sufficient inventory to meet market demands.

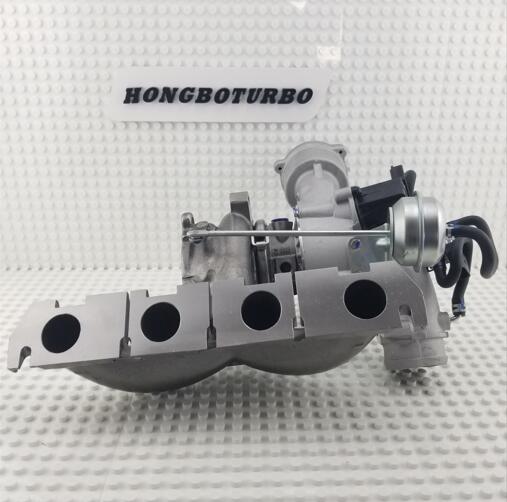

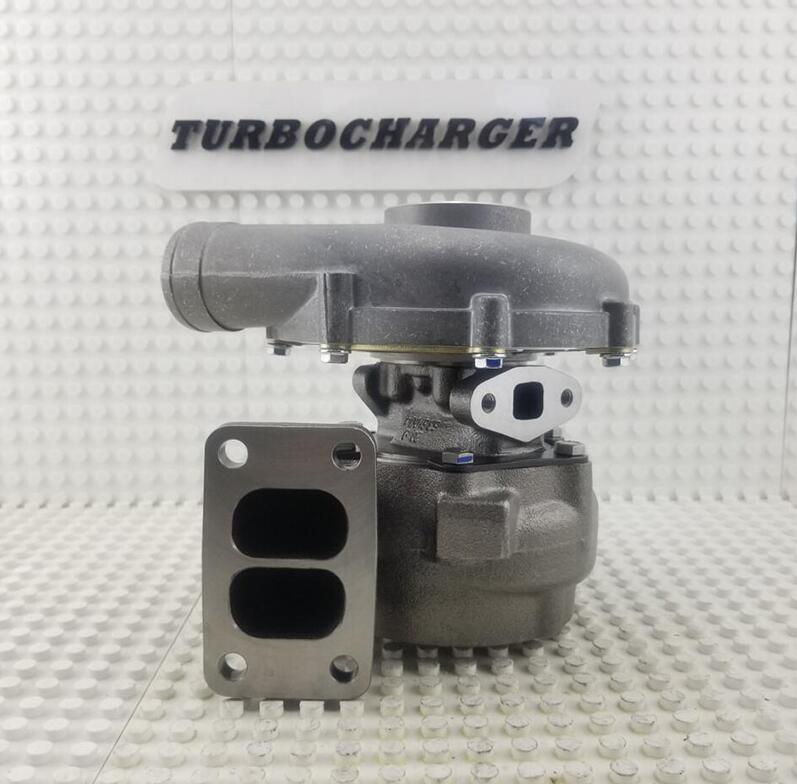

Product Display

3

4 | ||||

| Turbo mordel | SJ60F | weight | 6KG | |

| Material | K18 | Origin | China | |

| Specification | 25*15*28 CM | ETS Component | Turbine | |

| Production Capacity | 20,000 Pieces/Month | Quality Warranty Service | 1 year | |

SJ60F T74801002 Turbocharger

for perkins K18 material with SJ60F-1E Engine

| Product Description | ||||

| Turbo mordel | SJ60F | |||

| Part Number | T74801002 | |||

| OE Number | T74801002 | |||

| Engine | SJ60F-1E | |||

| Description | fits for | |||

| CHRA | 49178-09300 | |||

| Application | Mitsubishi Canter 60 LWK with 4D34T1 Engine 1990- Hyundai D4DA Mitsubishi 4D34T 3.9L 136HP | |||

Product Advantages

Engineered Application of K18 Heat-Resistant Alloy Material System

The turbine housing is cast using Perkins' proprietary K18 nickel-based superalloy, with columnar grain structure achieved through directional solidification technology. This enables the material to maintain a yield strength of over 320MPa even at a continuous operating temperature of 850°C, with thermal fatigue resistance enhanced by 40% compared to traditional 310S stainless steel. Combined with the mortise-tenon structure design of the Inconel 713C precision-forged impeller, it achieves a dynamic balance accuracy of ≤0.02mm at a high rotational speed of 120,000rpm, meeting the ISO 10816-4 vibration severity grade G1 standard.

Aerodynamic Efficiency Optimization of Dual-Channel Mixed-Flow Turbine

The SJ60F-1E-specific compressor impeller (112mm diameter, 32° sweep angle) and mixed-flow turbine (A/R ratio 0.82) combination, designed based on CFD flow field simulation, achieves an adiabatic efficiency of 76% in the engine's 1800-2200rpm economic operating range. It maintains a surge margin of over 90% even when the pressure ratio reaches 3.8:1, reducing exhaust backpressure by 18kPa compared to same-displacement radial flow turbine turbochargers, thereby increasing engine scavenging efficiency by 12%.

Intelligent Power Management with Electronically Controlled Variable Geometry Turbine

The variable nozzle ring mechanism (adjustment range 15°-45°) integrated with an electronic actuator receives real-time signals from the engine's MAP sensor via the ECU, completing turbine flow area adjustments within 200ms. This enables seamless switching between low-speed high torque (92% of peak torque at 1500rpm) and high-speed high power (280kW at 2200rpm). Combined with the Perkins EST diagnostic system, it achieves ±2% air-fuel ratio control accuracy, meeting the NOx limit requirements of the EU Stage V emission standard.

Total Cost of Ownership Optimization through Modular Integrated Design

The cartridge-type integral replacement structure (including bearing housing, seals, and thrust plate assembly) reduces maintenance and replacement labor hours by 60% compared to split structures. Coupled with the hardened alloy cast iron center housing (hardness HB220-250) and dual floating bearing (clearance 0.04-0.06mm) design, the turbocharger's MTBF (Mean Time Between Failures) reaches 12,000 hours, with B10 life (90% reliability) exceeding 20,000 hours, reducing overall operation and maintenance costs by 25%.

Quality Assurance

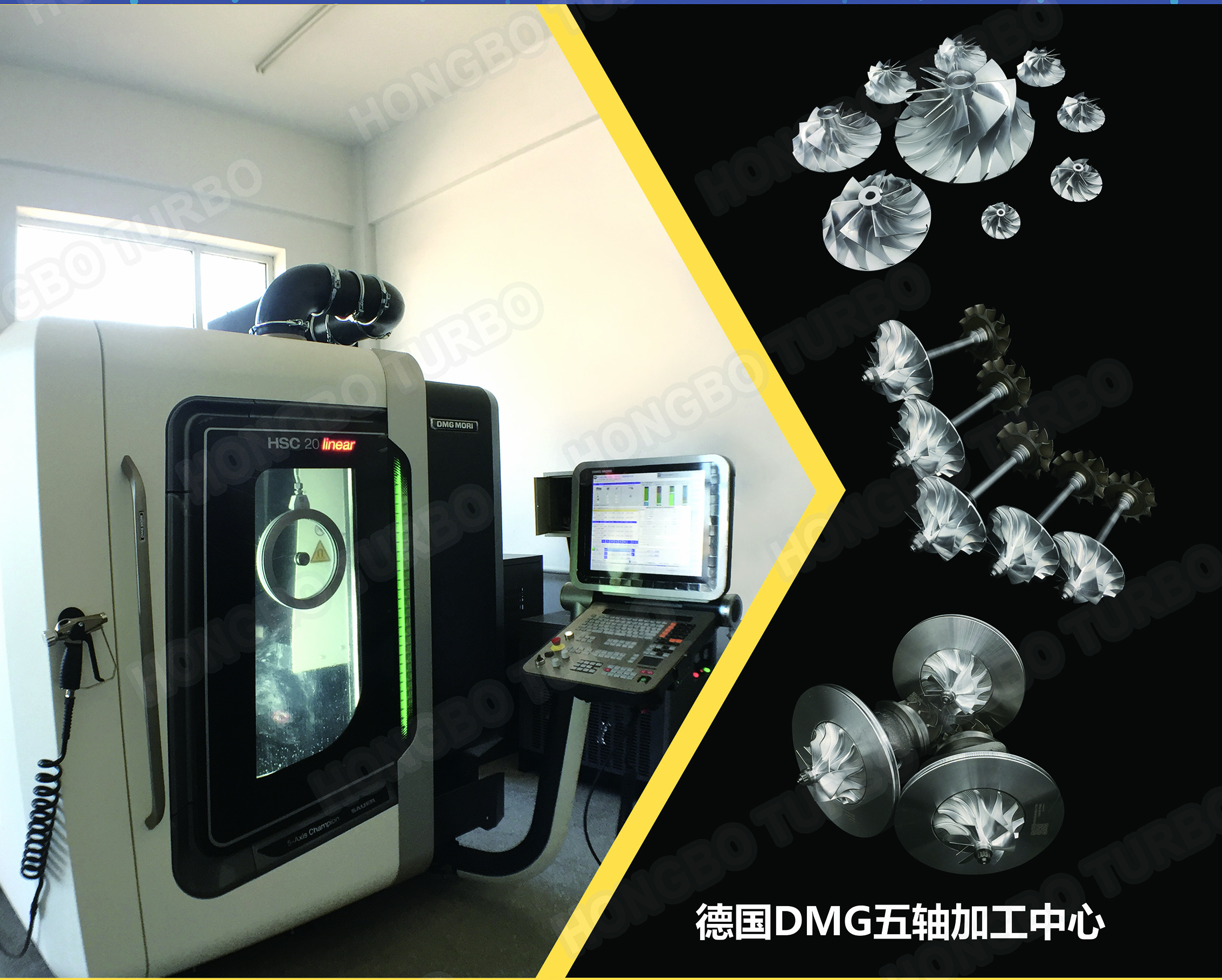

Our Equipment

About our company

Fengcheng Hongbo Turbocharger Parts Co., Ltd. located in Zone B of Erlong Industrial Park at No. 4, 3rd Road, is a versatile enterprise. With the automotive components industry as its core, we have seamlessly integrated production, design, and R&D into our business operations. Through years of accumulated expertise in turbocharger modification and performance optimization projects, we have successfully launched a host of upgraded products to the market.

Fengcheng Hongbo Turbocharger Parts Co., Ltd. looks forward to collaborating with you to achieve mutual benefits and a win-win outcome.

After Service

Contact us