K29 0040963599 A0040963599 53299887001 53299707001 Turbocharger for Mercedes Benz OM441LA Euro 1 Engine Parts Replacement

- Normal Brand

- Liaoning, China

- 10 days

- 20,000/Month

The turbine wheel of 0040963599 A0040963599 53299887001 53299707001 K29 turbocharger for Mercedes Benz OM441LA Euro 1 is treated with a thin, uniform plasma-sintered overlay that refines grain structure and seals micro‑fissures.

Product Description

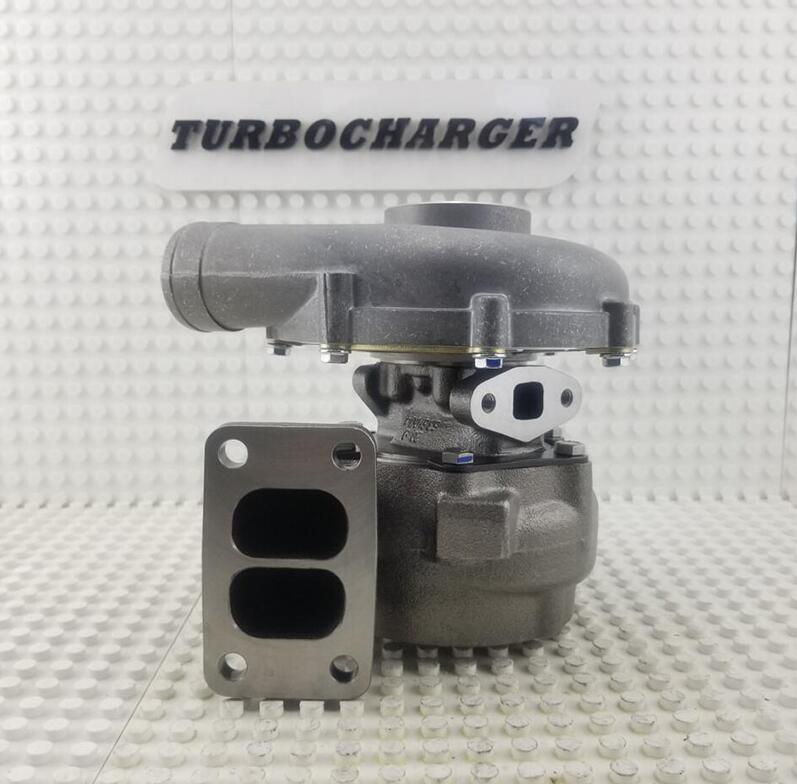

0040963599 A0040963599 53299887001 53299707001 K29 turbocharger for Mercedes Benz OM441LA Euro 1

OE Number | 0040963599 A0040963599 | Application Make | 1987- Mercedes Benz Commercial Bus with OM441LA Euro 1 Engine 1987- Mercedes-Benz 1834, Truck with OM441LA Euro 1 Engine |

Part Number | 53299887001 53299707001 | ||

| Turbo Model | K29 | ||

| Engine Code | OM441LA Euro 1 | ||

| Weight | 13 KG | ||

| Warranty | 1 Year | ||

| Specification | 25*15*26 cm | ||

| Product Capacity | 20,000 Pieces/Month |

Basic Info

Fuel | Diesel |

| Material | K18 |

| Cooled Type | Oil Cooled |

| CHRA | 53297100005 |

| Bearing Housing | 53271500016 |

| Turbine Wheel | 53291202101 |

| Comp. Wheel | 53291232202 |

| Back plate | 53291515704 |

| Heat shield Number | 53291652000 |

| Repair Kit | 53297110001 |

| Turbine Housing | 53291016500 |

| Compressor Cover | 53291015017 |

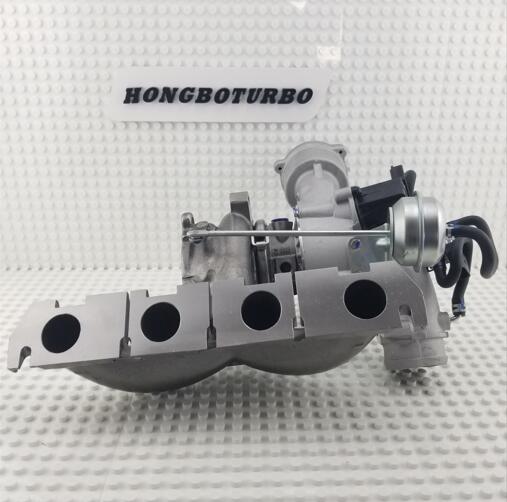

Product Display

0040963599 A0040963599 53299887001 53299707001 K29 turbocharger for Mercedes Benz OM441LA Euro 1

Products Advantages

Dual‑Stage Pulse Equalizer Scrolls:

A two‑tiered volute design separates high‑ and low‑pressure exhaust pulses into dedicated chambers, yielding up to 12 % better scavenging across the RPM range—so heavy‑load acceleration feels linear and immediate even under Euro 1 restrictions.

Plasma‑Enhanced Fatigue‑Resistant Wheel:

The turbine wheel of 0040963599 A0040963599 53299887001 53299707001 K29 turbocharger for Mercedes Benz OM441LA Euro 1 is treated with a thin, uniform plasma-sintered overlay that refines grain structure and seals micro‑fissures, increasing fatigue life by 30 % and ensuring consistent boost through millions of duty‑cycle hours.

Integrated Steam‑Flash Thermal Stabilizer:

A micro‑tube condensate circuit within the bearing housing uses exhaust steam to pre‑cool incoming oil, slashing peak bearing temperatures by 18 % during long haul or slow‑speed work and virtually eliminating coking under stop‑start conditions.

Helmholtz‑Tuned Acoustic Surge Baffle:

Encased in the compressor outlet is a compact Helmholtz chamber that fractures harsh pressure oscillations, cutting characteristic “whistle” noise by up to 5 dB at full boost—delivering a smoother, quieter engine note without impeding airflow.

Why Choose Us?

Our company operates in accordance with the modern enterprise management mode. It passed the CE quality system certification in 2023 and the ISO 9001 quality management system certification in 2017.

Certificate Attestation of Conformity

Quality Management System Certification Certificate

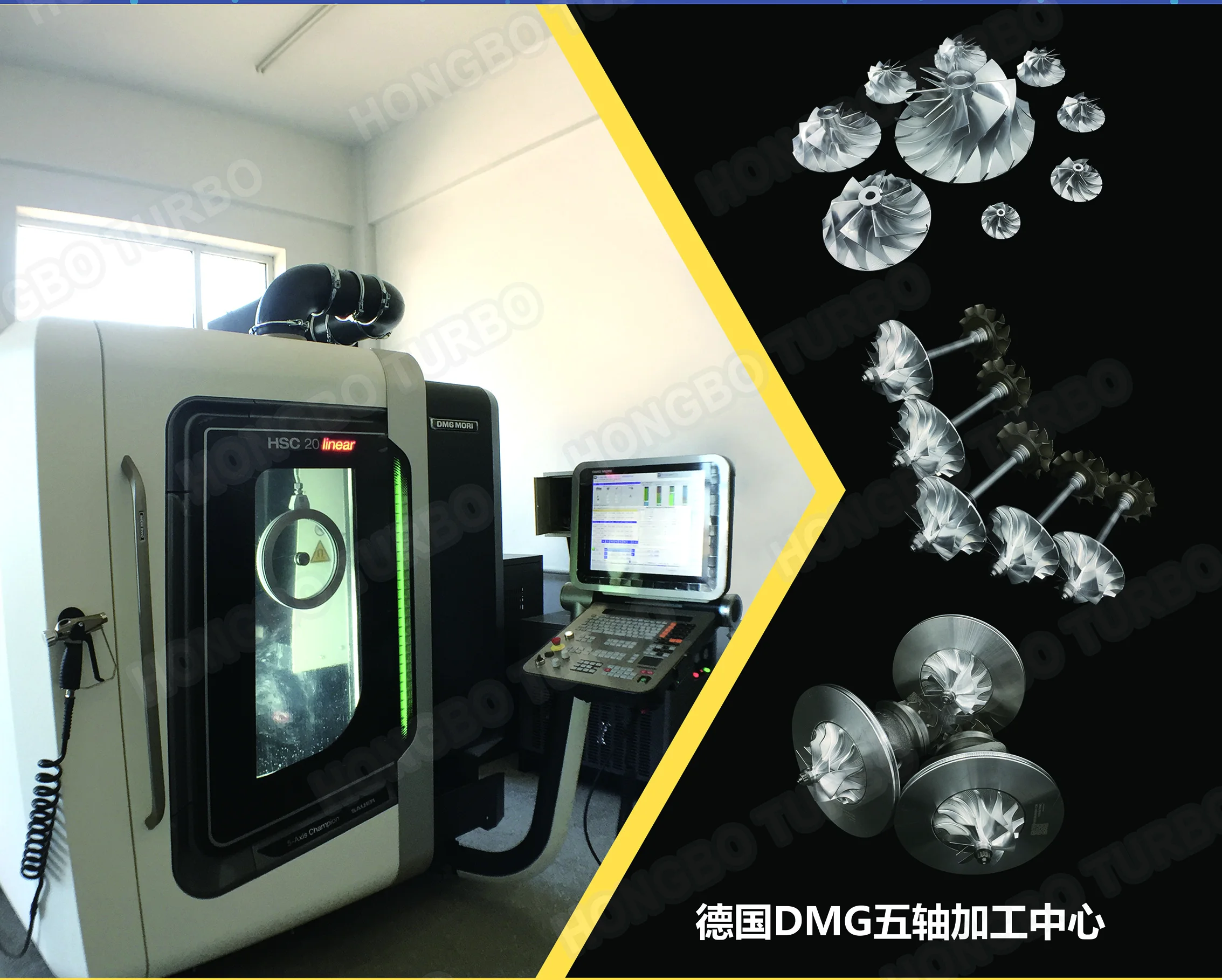

Automatic air floating billet wheel balance test

5-axis CNC machining center

3D automatic scanner

CORE-Balanling machine

Coordinate Measuring Machine

Turbojet engine test bench

Optical Measurement System

5-axis CNC machining center

About Our Company

Fengcheng Hongbo Turbo Co.,Ltd is specialized in manufacturing and maketing turbochargers and turbo components. Such as Cartridge, Billet wheel, Shaft wheel, Compressor wheel and so on. Our company have professional engineer, advanced technology, testing equipment and strict quality management system. Our company established in 2004, and we produces all turbochargers and turbo spare parts uses standard OE. Now we has more than 500 turbochargers and thousands of rotor assy.

Contact Us