Complete TD04L4-11TK3-VG Turbocharger 49477-01214 49477-01213 LR065510 for Land Rover Evoque 2.2 TD4 Parts Replacement 118

- Normal Brand

- Liaoning, China

- 10 days

- 20,000/Month

The CHRA’s bearing bores of 49477-01214 49477-01213 LR065510 TD04L4-11TK3-VG turbocharger for Land Rover Evoque 2.2 TD4 are cryogenically honed to mirror‑finish tolerances, reducing oil shear by 30%.

Product Description

49477-01214 49477-01213 LR065510 TD04L4-11TK3-VG turbocharger for Land Rover Evoque 2.2 TD4

OE Number | LR065510 LR049592 LR038309 LR038322 LR022358 | Application Make | Turbocharger For Land Rover Evoque 2.2 TD4 110Kw 150HP 2011- Turbocharger For Land Rover Evoque 2.2 SD4 TD4 140Kw 190HP 2011- Turbocharger For Land Rover Freelander II 2.2 TD4 110Kw 150HP 2010-2014 Turbocharger For Land Rover Freelander II 2.2 SD4 TD4 140Kw 190HP 2010-2014 |

Part Number | 49477-01214 49477-01213 49477-01204 49477-01203 49477-01202 | ||

| Turbo Model | TD04 | ||

| Engine Code | 224DT | ||

| Weight | 9 KG | ||

| Warranty | 1 Year | ||

| Specification | 25*15*26 cm | ||

| Product Capacity | 20,000 Pieces/Month |

Basic Info

Fuel | Diesel |

| Material | K18 |

| Cooled Type | Water Cooled |

Product Display

49477-01214 49477-01213 LR065510 TD04L4-11TK3-VG turbocharger for Land Rover Evoque 2.2 TD4

Products Advantages

Adaptive‑Vane Flow Control:

Precision‑engineered VNT vanes adjust their geometry in real time to match the Evoque’s varying exhaust back‑pressure, producing up to 15% quicker spool‑up at urban cruising speeds and seamless torque delivery when you floor it on the open road.

Cryogenically‑Honed Precision Bearings:

The CHRA’s bearing bores of 49477-01214 49477-01213 LR065510 TD04L4-11TK3-VG turbocharger for Land Rover Evoque 2.2 TD4 are cryogenically honed to mirror‑finish tolerances, reducing oil shear by 30%, cutting friction losses for lightning‑fast throttle response, and delivering bearing life measured in hundreds of thousands of miles.Integrated Boost‑Temp Sensor Module:

A compact, vibration‑isolated sensor cluster on the bearing housing feeds live boost pressure and oil‑temperature data directly to the ECU—enabling ultra‑precise boost control, proactive fault detection, and optimized tune maps for both performance and longevity.

Thermo‑Reactive Ceramic‑Matrix Coating:

The turbine housing’s inner surface is treated with a low‑emissivity ceramic‑matrix layer that dynamically modulates its thermal conductivity. This cuts heat‑soak time by 20%, stabilizes bearing‑housing temperatures on repeated pulls, and preserves oil viscosity for extended service intervals.

Why Choose Us?

Our company operates in accordance with the modern enterprise management mode. It passed the CE quality system certification in 2023 and the ISO 9001 quality management system certification in 2017.

Certificate Attestation of Conformity

Quality Management System Certification Certificate

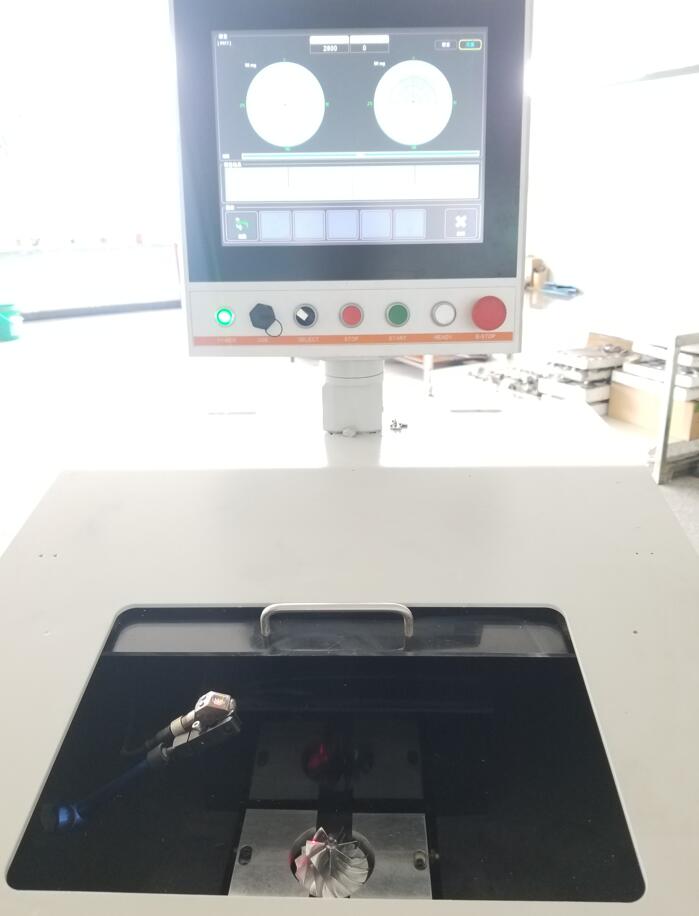

Automatic air floating billet wheel balance test

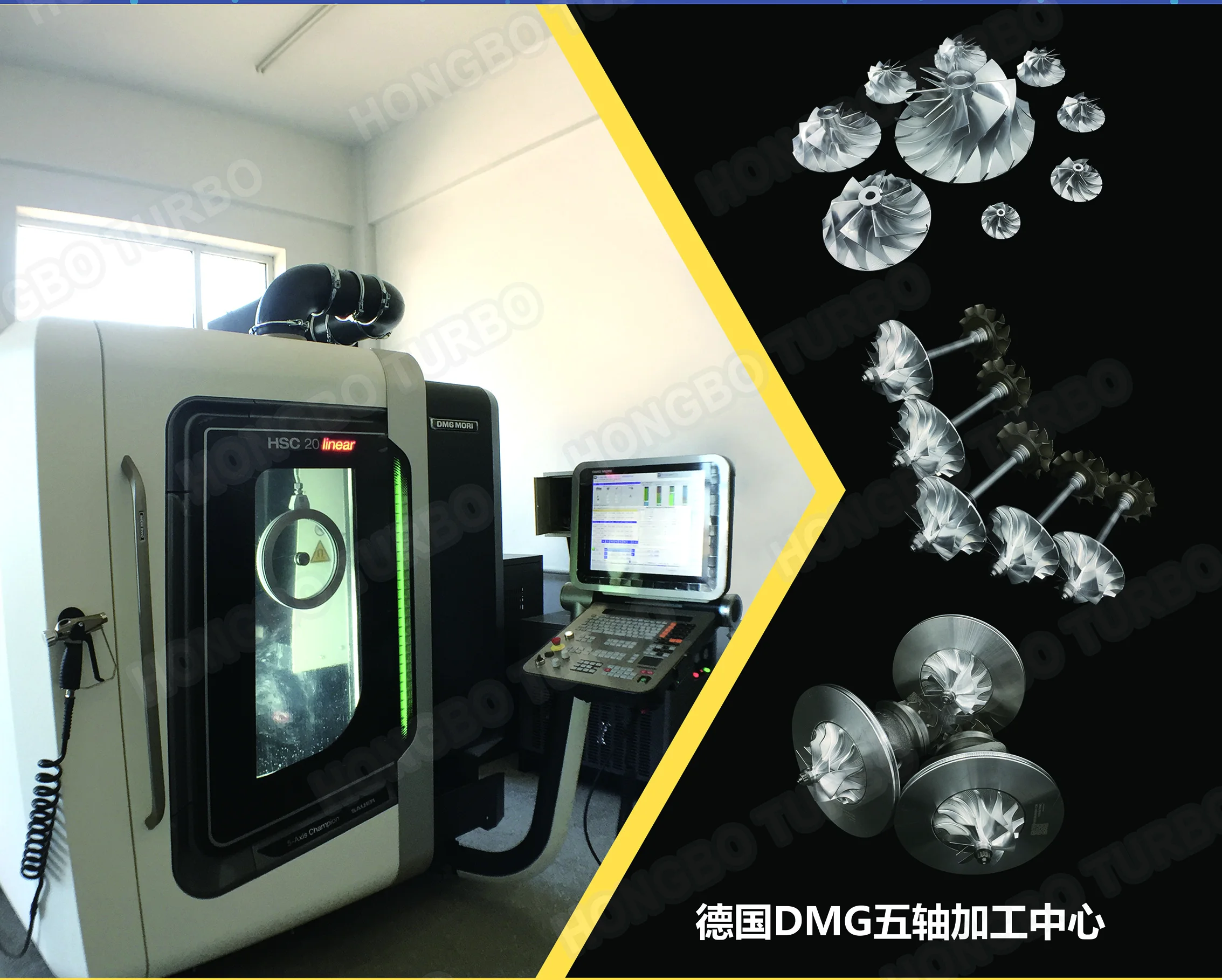

5-axis CNC machining center

3D automatic scanner

CORE-Balanling machine

Coordinate Measuring Machine

Turbojet engine test bench

Optical Measurement System

5-axis CNC machining center

About Our Company

Fengcheng Hongbo Turbo Co.,Ltd is specialized in manufacturing and maketing turbochargers and turbo components. Such as Cartridge, Billet wheel, Shaft wheel, Compressor wheel and so on. Our company have professional engineer, advanced technology, testing equipment and strict quality management system. Our company established in 2004, and we produces all turbochargers and turbo spare parts uses standard OE. Now we has more than 500 turbochargers and thousands of rotor assy.

Contact Us