Complete TD03 Turbocharger 49131-06320 BK3Q-6K682-NB for Ford Ranger 2.2L Engine Parts Replacement Upgrade

- Normal Brand

- Liaoning, China

- 10 days

- 20,000/Month

A built‑in mini‑reservoir in the CHRA housing of 49131-06320 BK3Q-6K682-NB TD03 turbocharger for Ford Ranger 2.2L Engine buffers oil during rapid load changes, preventing momentary starvation during throttle lift‑off and hill descents.

Product Description

49131-06320 BK3Q-6K682-NB TD03 turbocharger for Ford Ranger 2.2L Engine

OE Number | BK3Q-6K682-NB BK3Q-6K682-NA | Application Make | Turbocharger for Ford Ranger 2.2L Engine PUMA 2012 Turbocharger for Mitsubishi Version 2.2L |

Part Number | 49131-06320 49131-06300 49131-06340 | ||

| Turbo Model | TD03 | ||

| Engine Code | Ford 2.2 TDCI | ||

| Weight | 6 KG | ||

| Warranty | 1 Year | ||

| Specification | 25*15*26 cm | ||

| Product Capacity | 20,000 Pieces/Month |

Basic Info

Fuel | Diesel |

| Material | K18 |

| Cooled Type | Oil Cooled |

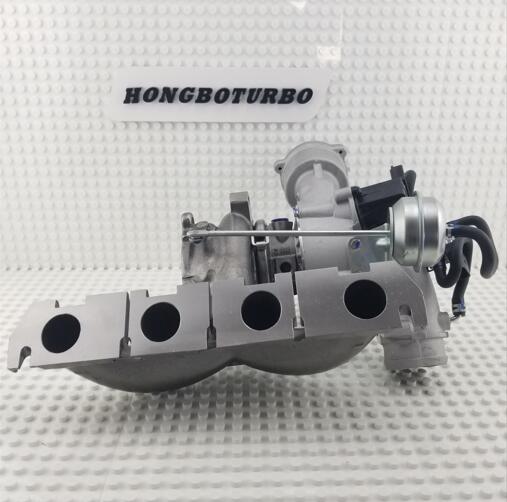

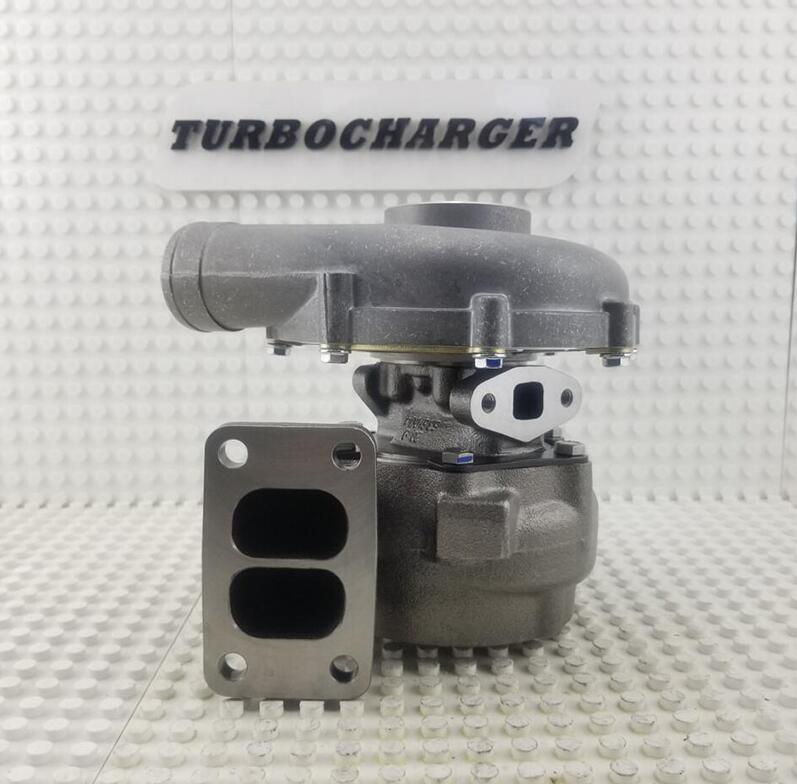

Product Display

49131-06320 BK3Q-6K682-NB TD03 turbocharger for Ford Ranger 2.2L Engine

Products Advantages

Ultra‑Low Inertia Compressor Wheel:

A precision‑machined, five‑axis aluminum‑alloy compressor wheel of 49131-06320 BK3Q-6K682-NB TD03 turbocharger for Ford Ranger 2.2L Engine reduces rotating mass by 20%, delivering lightning‑fast spool‑up and virtually eliminating low‑RPM lag—giving you immediate torque the moment you plant your foot.

Integrated Oil‑Surge Reservoir:

A built‑in mini‑reservoir in the CHRA housing of 49131-06320 BK3Q-6K682-NB TD03 turbocharger for Ford Ranger 2.2L Engine buffers oil during rapid load changes, preventing momentary starvation during throttle lift‑off and hill descents. The result: no more coking or bearing wear, even under hard off‑road or towing duty.

Acoustic Flow Harmonizer:

A patent‑pending helical diffuser integrated into the compressor outlet break ups high‑frequency pressure pulses, trimming “whistle” noise by up to 4 dB at peak boost and delivering a smoother, more refined engine note without sacrificing performance.

SmartSeal Labyrinth Inlet:

A multi‑stage, hydrophobic labyrinth seal at the compressor inlet centrifugally ejects moisture and fine particulates before they reach the bearing surfaces—extending rebuild intervals by 30% in dusty or wet environments while maintaining peak airflow.

Why Choose Us?

Our company operates in accordance with the modern enterprise management mode. It passed the CE quality system certification in 2023 and the ISO 9001 quality management system certification in 2017.

Certificate Attestation of Conformity

Quality Management System Certification Certificate

Automatic air floating billet wheel balance test

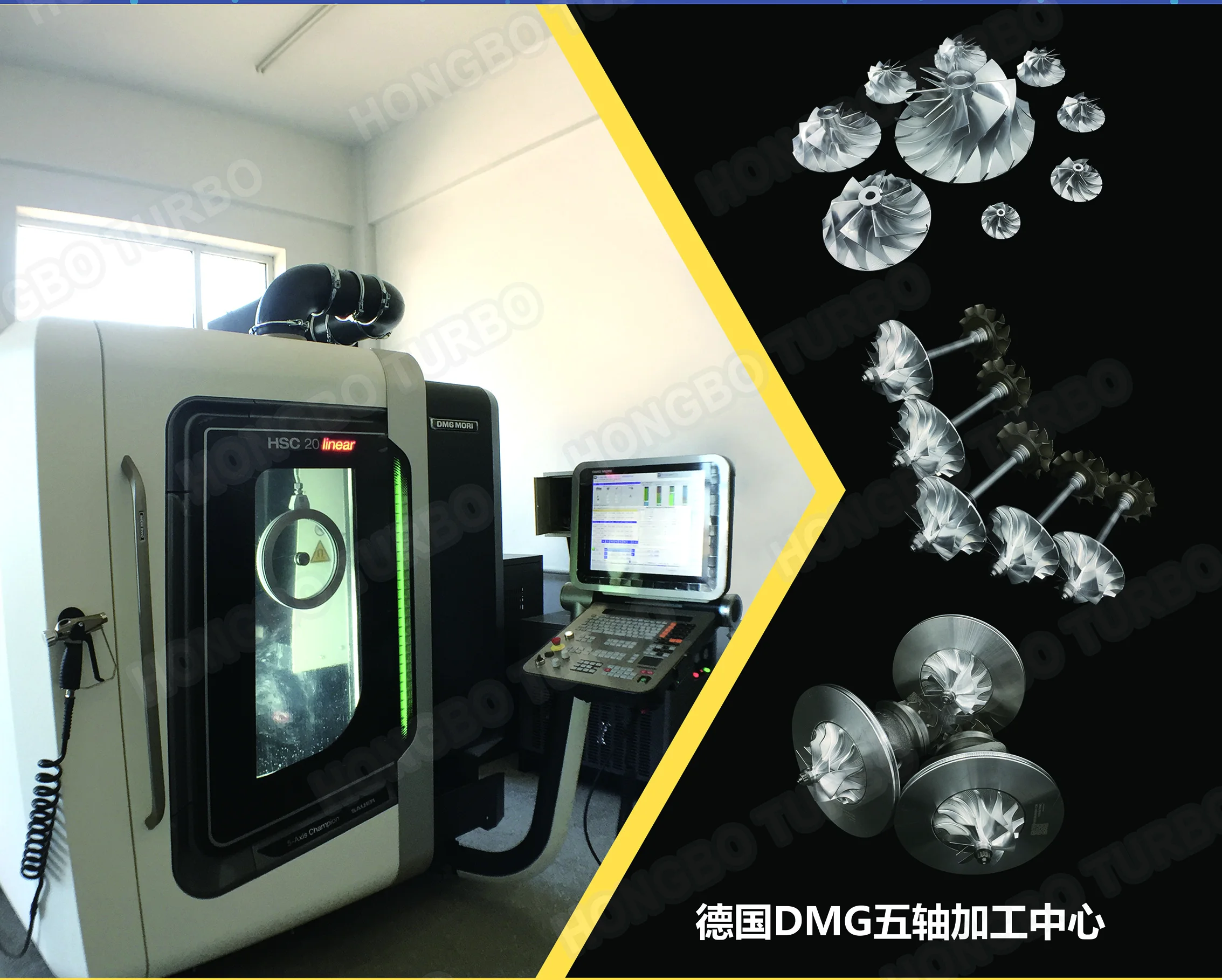

5-axis CNC machining center

3D automatic scanner

CORE-Balanling machine

Coordinate Measuring Machine

Turbojet engine test bench

Optical Measurement System

5-axis CNC machining center

About Our Company

Fengcheng Hongbo Turbo Co.,Ltd is specialized in manufacturing and maketing turbochargers and turbo components. Such as Cartridge, Billet wheel, Shaft wheel, Compressor wheel and so on. Our company have professional engineer, advanced technology, testing equipment and strict quality management system. Our company established in 2004, and we produces all turbochargers and turbo spare parts uses standard OE. Now we has more than 500 turbochargers and thousands of rotor assy.

Contact Us